SHILI CARBON

EXCELLENT MANUFACTURER & EXPORTER

There are a series of gouging carbons, gouging carbon rods, copper-coated gouging carbons, carbon electrodes, etc. We have 100 sizes, including pointed, jointed, flat, hollow cored and special shape ,etc. There is a wide range of electrode diameters available to choose from.

| DESCRIPTION OF AIR CARBON ARC GOUGING |

Air carbon-arc cutting (ACC) is a process of cutting, piercing, or gouging metal by heating it to a molten state and then using compressed air to blow away the molten metal, from around the gouging carbon electrodes

| GENERAL USAGE OF GOUGING CARBONS |

The general usage of gouging carbons is to cut steel panel, and to remove weld defects and weld beads.

The gouging carbon electrodes can be used in not only cutting various metals including steel plate, cast iron, steel alloys, stainless steel, manganese steel, copper alloys and similar metals, but also removing welding defects and welding beads.

| SHILI'S ADVANCED MANUFACTURING TECHNOLOGY |

We are proud to introduce SHILI Jointed Gouging Carbons manufacturing technology.

While traditional arc gouging operations, we are sure to have unnecessary stubs which should be thrown away,SHILICARBON. developed Joint type gouging carbon。

| SHILICARBON has merits as follow. |

* More than 25% of economical benefit by utilizing stubs, in addition to time-saving by reducing frequent rods change.

* SHILICARBON gouging carbons improve operations especially in vessels, gas pipe line, boilers, complex plants, and etc.

* Do not worry about damages facing shields from arc flames: Stable SHILICARBON arc flames gives you not only product satisfaction but also working safety.

* SHILICARBON increase productivity: Frequency of changing carbons can be reduced with SHILI Jointed Carbons.

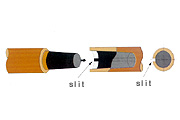

SHILICARBON Jointed Blasting Carbons have a long slit on the female sockets to facilitate the male tenon to insert female socket with easy by slight twist push. And carbon's natural elasticity secures the perfect carbon-to-carbon and copper-to-copper contact to provide optimum electrical conductivity, and prevent stub loss.

Pointed carbon electrodes

Pointed carbon electrodes Jointed carbon electrodes

Jointed carbon electrodes Special shape of shili(Rectangular, Groove, Hollow cored carbon)

Special shape of shili(Rectangular, Groove, Hollow cored carbon) Blasting carbon electrodes

Blasting carbon electrodes Graphite electrodes

Graphite electrodes